One of the pillars of our research is related to sensors and their integration. As known, sensors detect and measure physical and chemical properties, converting such information into data that can be used in different application areas. A careful study of both the design and manufacturing of a sensor is necessary to guarantee the reliability of the sensor itself. Likewise, correct integration of the sensor, and more generally of microelectronic devices including MEMS, can ensure correct and optimal functioning, as well as technological advancement of interest in the industrial application field.

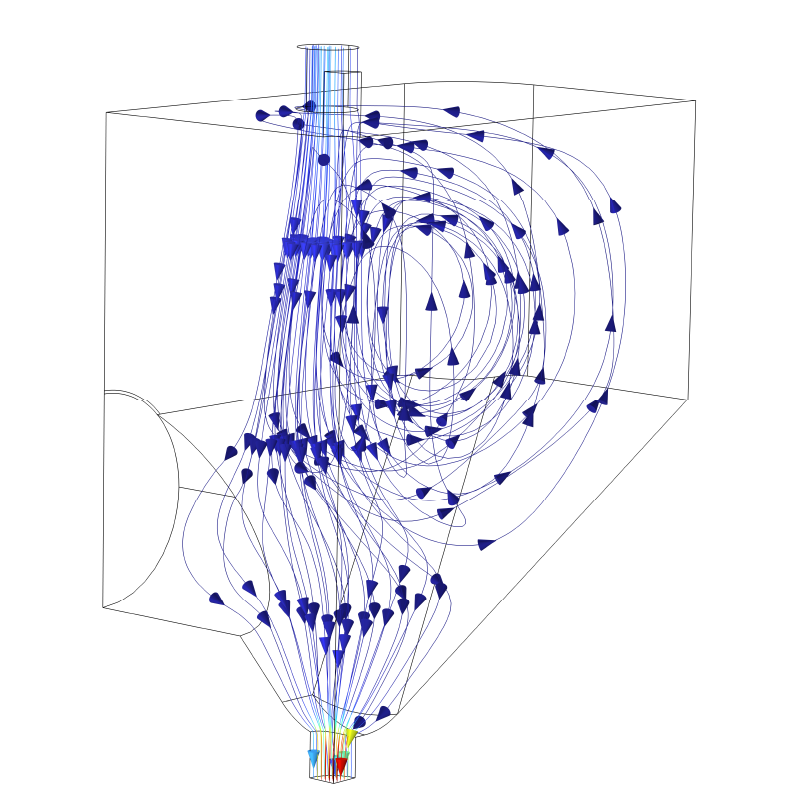

In the field of microelectronics, the growing need for integration requires scrupulous design and careful choice of materials. Co-design allows such engineering by parallelizing design and simulation. Thermal dissipation, mechanical behavior or electromagnetic compatibility can be addressed right from the first project draft with a notable saving of resources in the creation of optimized devices. Dedicated characterization tools provide useful data for simulation purposes. Before obtaining the physical device, the available software, through multiphysics interfaces, also allow the evaluation of multiple simultaneous phenomena in the study of the virtual device. For example, these analyses enable the estimation of stress in components, or the formation of hot spots.

Portable diagnostic tests, electronic devices, and microfluidic platforms share a dependence on their form for usability. The study of the package is therefore crucial in the manufacturing of prototypes. While in the past it was seen only as protection, today packaging can act as an active interface with the external environment. Therefore, it requires innovative production processes and technological standards. In particular, the future of microelectronics requires the study of materials, processes and instrumentation to create heterogeneous integrated devices according to the System In Package (SiP) philosophy, i.e. capable of assembling multiple functions operated by single chips in a single device , fabricated on different semiconductors. In its technology portfolio, the group has dedicated equipment such as additive manufacturing, assembly technologies and characterization tools.

The growing interest in wearable devices has highlighted the need to develop highly deformable sensors capable of mimicking human tactile perception or creating smart textiles for a wide range of applications. These devices integrate sensing units, energy systems, and electronics to create intelligent wearable products. Our group focuses on developing deformable sensors for detecting multiple physical, biological, and chemical parameters, leveraging expertise in materials and nanotechnologies to enhance functionality and sustainability. We also work on integrating energy harvesting and storage devices, enabling the development of self-powered flexible wearable devices.

Environmental monitoring of pollutants in water is crucial for both the protection of water resources and human health. Through the development of innovative, on/off-shore sensors, it is possible to perform in-situ analyses of water such as drinking water, groundwater and seawater. Assessing water quality at an early stage helps to counter contamination and optimize its use and availability. MP4MNT researchers also specialize in the development of Microbial Fuel Cell (MFC)-based sensors, with a specific focus on nanostructured electrodes, which are crucial for the optimization of extracellular electron transfer (EET) and sensing processes. MFC-based biosensors enable fast-response detection and demonstrate sensitivity to various toxic agents.